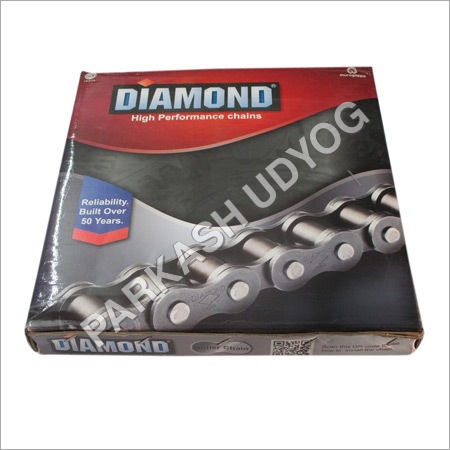

High Performance Chains

High Performance Chains Specification

- Features

- Corrosion Resistant, High Strength, Durable

- Shape

- Roller Chain

- Usage & Applications

- Industrial Machinery, Power Transmission, Conveyors

- Surface Finish

- Smooth

- Lubricating System

- Automated or Manual Lubrication

- Noise Level

- Low

- Size

- Custom Sizes Available

- Diameter

- As per specification

- Drive Type

- Mechanical

- Capacity

- High Load Bearing

- Product Type

- High Performance Chain

- Material

- Alloy Steel

- Technology

- Precision Engineering

- Power Source

- Manual

- Surface Treatment

- Polished

- Dimension (L*W*H)

- Customizable

- Weight

- As per size

- Color

- Silver/Grey

- Compatibility

- Works with Standard Sprockets

- Maintenance

- Low

- Links Type

- Solid & Bush

- Breaking Load

- Upto 25,000 kg

- Tensile Strength

- High

- Installation

- Easy to Install

- Pitch

- Standard and Custom

- Temperature Resistance

- Upto 250°C

High Performance Chains Trade Information

- Minimum Order Quantity

- 20 Units

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

About High Performance Chains

We are engaged in offering wide range of High Performance Chains to our clients. This product is manufactured using certified material and latest machining operation to ensure the quality and high performance of the product. The offered product is highly durable, has long life with excellent performance and long lasting operation without failure. We provide this High Performance Chains in the market at the reasonable price.

Features:

- Long lasting durability

- Precise dimension

- Sturdy construction

Engineered for Industrial Demands

These high performance chains are designed using precision engineering technology to meet the rigorous requirements of power transmission and conveyor systems in industrial environments. Their robust alloy steel construction, combined with customizable dimensions and pitches, ensures a perfect fit across diverse machinery and processes.

Superior Durability and Low Maintenance

The chains are manufactured with a polished, corrosion-resistant surface finish and can operate in temperatures up to 250C. Solid and bush link options, combined with an automated or manual lubrication system, extend the products lifespan and minimize the need for frequent upkeep.

Effortless Compatibility and Installation

Each chain is designed for seamless integration with standard sprockets and mechanical drive systems. The easy installation process and customizable sizing make them suitable for new projects or replacement in existing industrial setups, ensuring minimal downtime and consistent operational efficiency.

FAQs of High Performance Chains:

Q: How are these high performance chains installed in industrial machinery?

A: These chains are designed for easy installation and are compatible with standard sprockets and mechanical drive types. Custom sizing ensures a precise fit, while the lightweight yet robust design allows for quick setup even in challenging environments.Q: What makes these chains suitable for high load-bearing applications?

A: Their construction from alloy steel, with precision engineering and high tensile strength, allows them to handle breaking loads up to 25,000 kg. The solid and bush link types further enhance their ability to withstand heavy operational stresses.Q: When should I perform maintenance on these chains?

A: Thanks to their low-maintenance design and automated or manual lubrication options, maintenance intervals are significantly extended. However, regular inspections according to usage intensity and environmental conditions are recommended to ensure optimal performance.Q: Where can these chains be used within industrial settings?

A: They are ideal for a wide array of applications, including power transmission, conveyors, and industrial machinery that require high strength and reliable operation. Their adaptability makes them suitable for various sectors across India and beyond.Q: What is the process for ordering or customizing these chains?

A: Customers can specify their requirements regarding pitch, dimensions, and special features. As an exporter, importer, manufacturer, supplier, and trader, we offer consultation and fast turnaround on orders, including custom and bulk requests.Q: How does the automated lubrication system benefit chain performance?

A: The automated lubrication system ensures consistent, optimal lubrication of the chain, reducing friction and wear, which ultimately extends the chains life, decreases maintenance needs, and maintains quiet, smooth performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rice Milling Machines Parts Category

Rice Grader Spares

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Weight : Varies with spare part type

Dimension (L*W*H) : As per grader model

Color : Silver / Blue / Custom

Material : Mild Steel

Chains Coupling

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Weight : Depends on size (approx. 1kg 10kg)

Dimension (L*W*H) : Varies by model (customizable)

Color : Black / Metallic

Material : Alloy Steel

Rice Mill Screen

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Weight : Approx. 210 kg (varies by size)

Dimension (L*W*H) : Customized as per requirement

Color : Silver / Grey

Material : Mild Steel

Taper Bush

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Weight : Depends on size

Dimension (L*W*H) : Varies as per bush size

Color : Black / Grey

Material : High Grade Steel / Cast Iron

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese