Taper Bush

Taper Bush Specification

- Size

- Range from 1008 to 5050 Series (custom sizes available)

- Noise Level

- Silent operation

- Lubricating System

- No lubrication required

- Usage & Applications

- Power Transmission components, Pulley mounting, Gearbox coupling

- Shape

- Cylindrical with tapered bore

- Diameter

- Range as per bush series

- Drive Type

- Keyless taper lock

- Capacity

- High torque carrying capacity

- Features

- Easy to mount and dismount, Corrosion resistant, Provides exact and rigid centering

- Surface Finish

- Smooth

- Product Type

- Taper Bush

- Material

- High Grade Steel / Cast Iron

- Technology

- Precision Machined

- Power Source

- Manual

- Surface Treatment

- Phosphated, Blackodized or Plain

- Dimension (L*W*H)

- Varies as per bush size

- Weight

- Depends on size

- Color

- Black / Grey

Taper Bush Trade Information

- Minimum Order Quantity

- 20 Units

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Taper Bush

With enriched industry experience, we are providing an excellent range of Taper Bush. The bush is designed with utmost precision, and manufactured using best quality raw material and latest technology by our skilled professionals. The offered bush undergoes various quality tests in order to ensure its flawlessness. The product is corrosion resistant and has high strength. Clients can avail this Taper Bush from us at industry leading rates.

Features:

- Dimensional accuracy

- Rust resistance

- Precisely designed

Universal Compatibility and Reliable Fit

Engineered for versatility, this taper bush features a universal fit suitable for both metric and inch shafts. It provides secure and precise mounting in a wide variety of power transmission applications, including conveyor systems, gearboxes, and drive pulleys. Customizable bore sizes ensure an exact fit for your application, improving equipment performance and longevity.

Durable Construction with Corrosion Resistance

Manufactured from high-grade steel or cast iron, this bush undergoes advanced treatments like phosphating or blackodizing. These processes result in excellent rust resistance and a long-lasting, smooth surface finish. The robust material choice and precision machining deliver prolonged service life, reducing the frequency and cost of replacement.

Easy Installation and Minimal Maintenance

The taper bush allows for fast mounting and removal using a basic Allen key, streamlining installation and replacement. Its design requires no lubrication and ensures silent operation, minimizing maintenance downtime. High torque capacity and a rigid, keyless taper lock ensure a secure fit, even in demanding industrial environments.

FAQs of Taper Bush:

Q: How do I install a Taper Bush with standard fitment?

A: Installation is straightforward and requires an Allen key or hex wrench for tightening the locking screws. Simply align the bush with the shaft and pulley or coupling, insert the locking screws into the precision-tapped threads, and tighten them evenly to secure the bush in place.Q: What are the main benefits of using a Taper Bush in my machinery?

A: Taper Bushes provide reliable, keyless mounting with high torque capacity and silent operation. Their precision fit, corrosion resistance, and long service life minimize maintenance requirements, making them a cost-effective solution for power transmission applications.Q: When should I consider replacing my Taper Bush?

A: Due to optimal hardness and durable surface treatments, the bush typically lasts up to 5 years under standard operating conditions. It should be replaced if excessive wear, loss of fit, or surface corrosion is observed during routine inspections.Q: Where can Taper Bushes be used?

A: These bushes are widely employed in mechanical, electrical, material handling, and conveyor systems, as well as for mounting pulleys, coupling gearboxes, and other power transmission components.Q: What sizes and customization options are available?

A: Taper Bushes are available ex-stock in standard series ranging from 1008 to 5050 and can be customized for specific shaft diameters. Bore size, surface treatment, and packing options can all be tailored to meet individual requirements.Q: What maintenance is required for a Taper Bush?

A: The bush requires no lubrication due to its smooth, treated surface. Routine visual inspection during scheduled maintenance is recommended to ensure continued performance and rust resistance.Q: How does the bush ensure precise shaft alignment and secure fitting?

A: The cylindrical shape with a tapered bore design ensures exact centering and a solid, vibration-free connection between the shaft and mounted component, delivering precise and rigid alignment throughout operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rice Milling Machines Parts Category

Rice Mill Screen

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Material : Mild Steel

Capacity : Handles high throughput per operational hour

Features : High screening efficiency, wearresistant, long service life

Surface Finish : Smooth / Anticorrosive

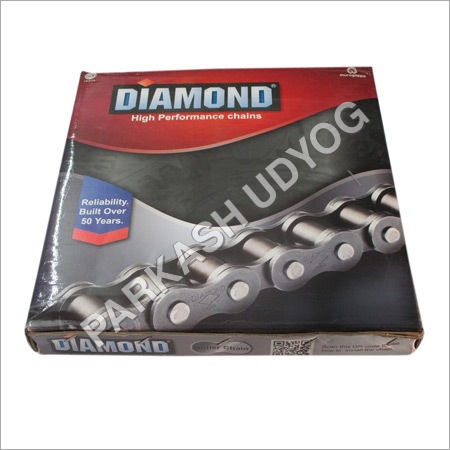

High Performance Chains

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Material : Alloy Steel

Capacity : High Load Bearing

Features : Corrosion Resistant, High Strength, Durable

Surface Finish : Smooth

Vibration Pad

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Material : High Grade Rubber

Capacity : Supports Loads up to 2000 kg

Features : AntiVibration, Shock Absorption, Durable, Easy Installation

Surface Finish : AntiSlip Textured

Bush Adapter Sleeves

Price Range 500.00 - 2000.00 INR / Unit

Minimum Order Quantity : 20 Units

Material : High Grade Steel

Capacity : Depends on model and application

Features : Corrosion resistant, precision engineering, easy fitting and removal

Surface Finish : Polished / Coated

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese